When it comes to vehicle maintenance, ensuring that all components are properly lubricated is essential for optimal performance and longevity. Tie rod ends, which play a crucial role in a vehicle’s suspension system, require regular greasing to function smoothly. However, there is a common misconception that more grease is always better. In fact, over greasing tie ends can have detrimental effects on their performance and lifespan.

We will delve into the topic of “over greasing tie rod ends,” exploring the dangers and consequences of excessive grease, identifying the signs of over greasing, understanding the proper grease types and applications, and providing best practices to avoid over greasing.

Understanding Tie Rod Ends

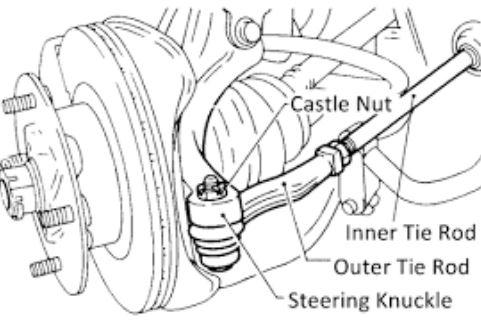

Tie rod ends are an essential component of a vehicle’s steering system. They connect the steering gear or rack to the steering knuckle, allowing the vehicle to turn and maneuver. Understanding how to tie ends work and how to maintain them is important for ensuring safe and reliable vehicle operation.

Tie ends are ball and socket joints that allow for movement and flexibility in the steering system. They consist of an inner and outer tie rod end, connected by a threaded rod. The outer tie rod end connects to the steering knuckle, while the inner tie rod end connects to the steering gear or rack.

As the driver turns the steering wheel, the steering gear or rack moves the inner tie rod end, which in turn moves the outer tie rod end and the steering knuckle. This movement allows the wheels to turn and steer the vehicle.

Over time, tie ends can wear out or become damaged, causing issues with steering and handling. Signs of worn or damaged tie ends include steering wheel vibration, uneven tire wear, and a loose or wandering steering feel.

Regular maintenance of tie ends is important for ensuring safe and reliable vehicle operation. This includes checking for wear and damage during routine inspections, and replacing any worn or damaged tie ends as needed. It is also important to have the vehicle’s alignment checked and adjusted as necessary, as misaligned wheels can put additional strain on the tie ends and cause premature wear.

The Role of Grease in Tie Rod Ends

The tie rod ends are crucial components of a vehicle’s steering system, responsible for connecting the steering knuckles to the steering rack or gearbox. These rod ends allow for smooth movement and control of the wheels, enabling the vehicle to turn left or right as directed by the driver. One crucial element in ensuring the optimal performance and longevity of rod ends is the use of grease.

Grease plays a significant role in the function of tie rod ends as it serves as a lubricant that reduces friction and wears between the moving parts. Tie ends have ball joints that are designed to pivot and move freely, allowing for smooth steering motion. Over time, these ball joints can experience wear and tear due to constant movement and exposure to harsh road conditions. Grease acts as a protective barrier, reducing friction and minimizing wear on the ball joints, thus extending their lifespan.

Moreover, grease in tie rod ends also helps to prevent corrosion. As tie rod ends are exposed to various environmental factors such as dirt, moisture, and road salt, they can be prone to rust and corrosion. Grease forms a protective barrier that seals out these contaminants, preventing them from reaching the metal surfaces of the tie ends and causing corrosion. This helps to maintain the integrity of the tie ends and ensures smooth steering operation.

Proper lubrication with grease also helps to reduce noise and vibrations. As the tie rod ends to move and pivot, it can create friction and vibrations that may result in noise and discomfort for the driver and passengers. Grease acts as a cushion, absorbing the impact and reducing vibrations, resulting in quieter and smoother steering operation.

Regular maintenance of tie ends, including greasing, is essential to ensure optimal performance and longevity. It is recommended to follow the vehicle manufacturer’s maintenance schedule and use the appropriate type of grease recommended for the tie ends. Over greasing or degreasing can both have negative consequences. Over greasing can lead to excess grease accumulating around the tie rod ends, attracting dirt and contaminants while under-greasing can result in insufficient lubrication, leading to increased friction and wear.

Over Greasing Tie Rod Ends: Dangers and Consequences

Over-greasing tie rod ends, which are an integral part of a vehicle’s steering system, can lead to various dangers and consequences. Tie ends are ball joints that connect the steering rack to the wheel spindles, allowing the driver to control the direction of the vehicle. Proper lubrication is essential for their smooth functioning, but over greasing can have detrimental effects.

One danger of over greasing tie ends is that excess grease can accumulate and seep out of the joint, leading to contamination of other steering components. This can cause the grease to spread to areas where it shouldn’t be, such as the brake rotors or brake pads, reducing their effectiveness and compromising the safety of the vehicle. Contaminated brakes can result in reduced braking performance, longer stopping distances, and increased risk of accidents.

Furthermore, over greasing tie rod ends can cause the excess grease to harden and form a thick layer around the joint. This can result in increased friction and resistance, making it harder for the steering system to move smoothly. As a result, the driver may experience difficulty in steering the vehicle, leading to poor vehicle control and an increased risk of accidents, especially at higher speeds or during emergency maneuvers.

Over-greasing tie ends can also lead to premature wear and tear of the joint itself. The excess grease can cause the boot or protective cover of the joint to rupture, allowing dirt, debris, and moisture to enter, leading to accelerated corrosion and damage to the ball joint. This can cause the tie rod end to fail prematurely, resulting in a loss of steering control and posing a significant safety hazard to the driver and passengers.

Identifying Over Greased Tie Rod Ends

Tie ends are critical components of a vehicle’s steering system that connect the steering linkage to the wheels. They allow for smooth and precise steering control, ensuring the safe operation of the vehicle. Proper lubrication is essential for tie rod ends to function effectively, but over greasing can lead to various issues that can affect the performance and longevity of these components.

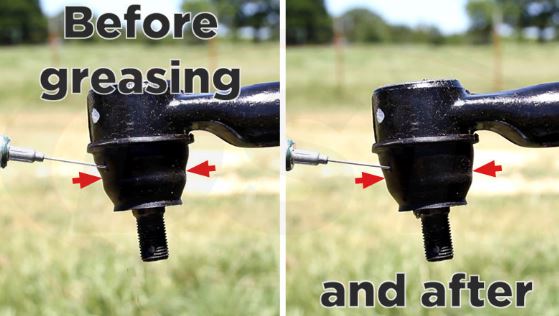

Over-greasing tie ends can occur when an excessive amount of grease is applied during routine maintenance or when using a grease gun. Grease is used to lubricate the joint and prevent friction, wear, and corrosion. However, too much grease can cause problems, and it’s important to be able to identify when tie ends have been over-greased.

One common sign of over-greased tie rod ends is excessive grease around the joints. When tie rod ends are properly lubricated, a thin layer of grease should cover the joint surfaces. However, if there is an excessive amount of grease visible around the tie rod end, it may indicate over greasing. The excess grease can attract dirt, dust, and other debris, leading to increased friction and accelerated wear of the joint.

Another indicator of over-greased tie ends is a squishing or squelching sound coming from the steering system when turning the wheel. Over greasing can cause the excess grease to be displaced and trapped between the joint surfaces, resulting in a squishing or squelching noise as the steering system operates. This can be particularly noticeable when making sharp turns or maneuvering at low speeds.

Over-greasing tie rod ends can cause the grease to be forced out of the joint, leading to a mess of grease on the wheel or surrounding areas. This can be easily visible upon visual inspection of the tie rod ends and their surroundings. If you notice an excessive amount of grease splattered around the tie ends or the surrounding areas, it may indicate over greasing.

Over-greasing tie ends can also cause increased steering effort or a “stiff” feeling in the steering system. The excess grease can create additional resistance within the joint, making it harder to turn the steering wheel smoothly. This can affect the overall steering performance and responsiveness of the vehicle.

It’s important to address over-greased tie ends promptly to prevent further issues. If you suspect that your tie ends have been over-greased, it’s recommended to consult a qualified mechanic for inspection and potential re-greasing or replacement of the tie rod ends as needed. Proper lubrication is crucial for the optimal performance and longevity of tie rod ends, and maintaining the right amount of grease is essential for safe and efficient steering operation in your vehicle.

Best Practices for Greasing Tie Rod Ends

- Follow the manufacturer’s recommendations: It’s essential to consult the vehicle’s owner’s manual or the manufacturer’s recommendations for the correct type of grease to use and the recommended greasing interval. Different types of vehicles may have different requirements, and using the wrong type of grease or greasing too frequently or infrequently can cause damage.

- Clean the tie rod ends before greasing: Before applying grease, it’s crucial to clean the tie ends thoroughly to remove any dirt, debris, or old grease that may have accumulated. Use a suitable cleaning solvent or degreaser and a clean cloth or brush to ensure that the tie ends are free from contaminants.

- Use high-quality grease: It’s important to use high-quality, automotive-grade grease that is specifically designed for tie ends or ball joints. Avoid using general-purpose or low-quality greases that may not provide sufficient protection and lubrication for the tie ends. The grease should have the correct viscosity and temperature range for the vehicle’s operating conditions.

- Apply the grease evenly: When applying grease, it’s crucial to do so evenly and in the right amount. Over greasing or under-greasing can both be detrimental to the tie rod ends. Follow the manufacturer’s recommendations for the appropriate amount of grease to apply, usually expressed in grams or cubic centimeters, and distribute it evenly around the tie rod end’s boot or zerk fitting.

- Inspect the tie rod ends regularly: Regular visual inspection of the tie ends is essential to detect any signs of wear, damage, or lack of grease. Look for cracks, tears, or deformities in the tie rod end boots, as well as any signs of grease leakage or contamination. If any issues are detected, address them promptly to prevent further damage or safety hazards.

- Use the correct greasing technique: Greasing tie rod ends typically involves using a grease gun and a zerk fitting, which is a small fitting that allows grease to be injected into the tie rod end. Use the correct size and type of grease gun and attachment for the zerk fitting, and apply steady pressure to inject the grease slowly until it starts to come out of the boot or fitting.

- Avoid over greasing: Overgreasing can cause the boot to become overfilled and create excess pressure inside the tie rod end, leading to premature wear, damage, or even failure. Avoid over greasing by following the manufacturer’s recommendations for the appropriate amount of grease to apply and monitoring the flow of grease as you inject it to ensure it doesn’t become excessive.

- Record and track greasing maintenance: Keeping a record of when and how the tie rod ends were greased can help track maintenance and ensure that they are greased at the appropriate intervals. Note down the date, type of grease used, amount applied, and any observations made during the inspection. This information can be valuable for future maintenance and troubleshooting.

Avoiding Over Greasing: Tips and Techniques

- Use non-stick cookware: Non-stick pans and grills require less grease compared to traditional cookware. The non-stick coating helps prevent food from sticking, reducing the need for excess grease. When using non-stick cookware, follow the manufacturer’s instructions and recommendations for greasing to avoid overdoing it.

- Use cooking sprays: Cooking sprays are a convenient way to apply a thin layer of oil to your cookware. They allow you to control the amount of grease you use and evenly distribute it. Be sure to hold the spray at a sufficient distance from the cookware to ensure a thin and even coating, and avoid spraying for too long, as this can lead to over greasing.

- Opt for healthier cooking oils: Choose healthier oils such as olive oil, avocado oil, or coconut oil, which are rich in monounsaturated fats or healthy fats. These oils are better for your heart health and can be used in smaller amounts compared to oils high in saturated fats, such as butter or lard. Using a brush or a paper towel to lightly coat your cookware with these oils can help you avoid over greasing.

- Season your cookware: Properly seasoned cast iron cookware can develop a naturally non-stick surface, reducing the need for excessive grease. To season your cookware, heat it on low heat, apply a thin layer of oil, and let it heat until the oil reaches its smoke point. Then, wipe off the excess oil with a paper towel, leaving a thin layer to protect the surface. Regularly seasoning your cookware can help you maintain its non-stick properties and avoid over greasing.

- Be mindful of recipe instructions: Many recipes specify the amount of grease needed, so be sure to follow them closely. Use the recommended amount of oil or butter and avoid adding extra grease unless necessary. Keep in mind that some ingredients, such as meat, naturally release fat during cooking, so additional grease may not be needed.

- Drain excess grease from cooked food: If you find that your cooked food is swimming in excess grease, use a slotted spoon or a paper towel to absorb the excess fat. This can help you reduce the overall grease content of your dish and make it healthier.

- Experiment with alternative cooking methods: Some cooking methods, such as baking, broiling, or steaming, require little to no grease. Experiment with different cooking techniques that can help you reduce the amount of grease needed in your recipes.

Effects of Over Greasing on Vehicle Performance

- Increased Friction: Over greasing can actually increase friction between moving parts instead of reducing it. When too much grease is applied, it can create a thick layer of grease that leads to higher resistance and friction, hindering the smooth movement of components. This can result in reduced performance, increased fuel consumption, and even damage to parts such as bearings, joints, and gears.

- Heat Buildup: Grease is designed to dissipate heat generated by friction between moving parts. However, over greasing can lead to excessive heat buildup as the excess grease can obstruct proper heat dissipation. This can result in overheating of components, such as bearings, causing them to wear out prematurely and reduce overall vehicle performance.

- Contamination: Over greasing can also lead to contamination of other vehicle components. Excess grease can attract dust, dirt, and debris, forming a thick layer of sludge that can clog or damage parts such as seals, gaskets, and filters. Contaminated components can lead to reduced performance and even failure, requiring costly repairs or replacements.

- Excessive Grease Consumption: Over greasing can lead to unnecessary consumption of grease, resulting in increased maintenance costs. Excessive grease may not be effectively utilized, and the excess grease may end up being wasted or requiring more frequent replacements. This can also have environmental impacts due to increased waste generation.

- Increased Maintenance Frequency: Over greasing can result in increased maintenance frequency as the excess grease can cause problems such as leaks, seal damage, and contamination. This can lead to more frequent maintenance tasks, such as cleaning, re-greasing, and component replacements, which can increase downtime and reduce overall vehicle performance.

FAQs About Over Greasing The Tie Rod

How can I identify if my tie rod ends have been over-greased?

Signs of over greasing tie ends may include grease oozing out from the dust boot or excess grease buildup around the joint. Additionally, if the tie ends feel excessively stiff or bind during movement, it may indicate over greasing.

Can over greasing tie rod ends cause steering issues?

Yes, over-greasing tie ends can negatively impact steering performance. The excess grease can create resistance in the joint, affecting the smooth operation of the steering system and compromising vehicle handling.

How often should I grease my tie rod ends to avoid over greasing?

It is essential to follow the manufacturer’s recommendations for greasing intervals and amounts. Typically, tie ends should be greased at regular maintenance intervals or when signs of insufficient grease are observed, and over greasing should be avoided.

Can I use any type of grease for tie rod ends?

It is important to use the type of grease recommended by the vehicle manufacturer for tie ends. Using the wrong type of grease or mixing different greases can lead to improper lubrication and potential damage to the tie ends.

How can I prevent over greasing tie rod ends?

To prevent over greasing, it is crucial to follow the manufacturer’s recommendations for greasing intervals and amounts. Using a grease gun with a pressure gauge can also help control the amount of grease applied. Properly inspecting tie ends for signs of over greasing during maintenance checks is also important.

What should I do if I suspect my tie rod ends have been over-greased?

If you suspect over greasing of tie ends, it is recommended to consult with a qualified mechanic or technician for proper diagnosis and potential corrective actions, such as cleaning out excess grease and reapplying the appropriate amount.

Why is proper greasing important for tie rod ends?

Proper greasing is crucial for tie ends as it ensures smooth operation, reduces friction and wear, and extends their lifespan. It also helps maintain optimal steering performance and contributes to overall vehicle safety and reliability.

Is over greasing tie rod ends a common issue?

Yes, over greasing tie ends is a common issue that can occur due to misconceptions about grease application or lack of knowledge about proper maintenance practices. It is important to understand the potential dangers and consequences of over greasing to avoid this issue.

Final Thought

In the end, understanding the risks associated with over greasing tie ends is crucial for maintaining the longevity and performance of your vehicle’s suspension system. Over greasing tie rod ends can lead to premature wear and damage, negatively impacting vehicle handling, tire wear, and steering responsiveness. It is important to follow the manufacturer’s recommendations and best practices for greasing tie ends to prevent over greasing and ensure proper maintenance.

Related Topic:

- When to Use White Lithium Grease on Rubber Bushings

- How To Remove Grease From Hands And Nails

- Where to Put Dielectric Grease on Spark Plugs

- What Happens If You Don’t Grease Brake Pads

- Different Types of Grease

- Can You Use Dielectric Grease on Brake Caliper Pins

- White Lithium Grease vs WD-40

- Is Red and Tacky Grease Good for Wheel Bearings

- what happens if you don’t grease your ball joints