If you have a car you are aware of how crucial maintaining it is. The ball joint is one of the most important parts of your car’s suspension system. It connects the control arm to the steering knuckle, allowing for smooth steering and suspension movement. As with any other car part, ball joints need proper maintenance to ensure they work optimally and last long. In this guide, we will show you how to grease a ball joint, a crucial step in joint maintenance.

Understanding Ball Joints

These joints are a necessary part of many different kinds of vehicles, such as cars, trucks, and SUVs. These small but critical parts are responsible for allowing your vehicle’s suspension to move up and down while keeping your wheels in line with your steering system. Understanding joints can help you diagnose issues with your suspension system and keep your vehicle running smoothly.

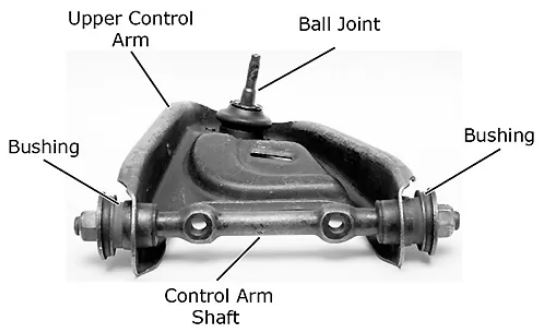

A joint consists of a spherical bearing and a metal socket that is attached to the control arm of your vehicle’s suspension system. The spherical bearing is enclosed in a metal housing that is filled with grease to help lubricate the joint and reduce friction. When the suspension system moves up and down, the joint allows the wheel and tire to follow the movement while remaining in line with the steering system.

Joints can become worn or damaged due to normal wear and tear, driving on rough roads, or exposure to harsh weather conditions. When this happens, the joint can become loose or fail completely, which can lead to a number of issues with your vehicle’s suspension, including uneven tire wear, a shaking steering wheel, or a vehicle that pulls to one side.

It is crucial to have your car checked out by a trained mechanic as soon as you detect a problem with your ball joints. A skilled technician can diagnose the problem and replace any worn or damaged ball joints, helping to ensure that your vehicle’s suspension system continues to operate smoothly and safely.

Tools Needed

- Grease gun – You will need a grease gun to inject grease into the joint. Make sure to choose a grease gun with a flexible hose to reach tight spots easily.

- Grease – You will need to choose the right type of grease for your ball joint. Check your vehicle’s owner’s manual for the recommended type of grease. Lithium-based or synthetic grease is commonly used for joints.

- Jack and jack stands – You will need to lift your vehicle off the ground to access the ball joint. A jack and jack stand will help you do this safely.

- Wrenches – You will need a wrench to remove the zerk fitting, the small metal nipple located on the ball joint, before greasing.

- Gloves – Grease can be messy and difficult to clean. Wearing gloves will protect your hands from getting greasy.

- Rags – You will need clean rags to wipe off excess grease and keep your work area clean.

- Wearing Safety Goggles – To shield your eyes from grease and particles, safety goggles are always a smart idea.

How to Inspect a Ball Joint

- Park the vehicle on a level surface and set the parking brake. Before starting the inspection, turn off the engine and allow the vehicle to cool.

- Locate the ball joint on the suspension. Depending on the type of suspension system, joints may be located at the top or bottom of the steering knuckle or control arm.

- Inspect the rubber boot that covers the ball joint. Look for any signs of cracking, tearing, or damage to the boot. The rubber boot is essential in keeping dirt, debris, and moisture out of the joint, and if it is damaged, the joint is more likely to fail prematurely.

- Check for excessive play in the ball joint. With one hand, grip the steering knuckle or control arm near the joint and attempt to move it up and down or side to side. If the joint moves excessively or feels loose, it may be worn out and need to be replaced.

- Look for signs of wear on the joint. If the rubber boot is intact and there is no excessive play, inspect the joint itself for signs of wear. Look for any visible cracks, corrosion, or pitting on the joint. To get a better look, you might also wish to use a flashlight.

- Check for grease. Some joints are designed to be greased regularly, while others are sealed and do not require lubrication. If the joint has a grease fitting, make sure that it has been recently lubricated and that the grease is not contaminated or dried out.

- Repeat the inspection on the other joint(s) on the suspension.

When to Grease a Ball Joint

Ball joints are an essential part of a vehicle’s suspension system. They connect the steering knuckles to the control arms and allow for the smooth movement of the wheels. Joints can become worn or damaged, leading to problems with steering and handling. To prevent this, it is important to regularly grease joints.

So when should you grease a ball joint? The answer to this question depends on the type of joint and the manufacturer’s recommendations. Some joints come pre-greased and do not require additional lubrication. Others may require lubrication every 12,000 to 15,000 miles or as often as every oil change.

To determine when to grease your joints, consult your vehicle owner’s manual or the manufacturer’s recommendations. You can also inspect the joint for signs of wear or damage. If the boot covering the joint is cracked or torn, or if you hear a clunking noise when turning or going over bumps, it may be time to grease or replace the joint.

Greasing a ball joint is a relatively simple process that can be done with a grease gun. First, locate the grease fitting on the joint. Then, attach the grease gun to the fitting and pump in the recommended amount of grease. It is important not to over-grease the joint, as this can cause damage.

Preparing to Grease a Ball Joint

- Identify the ball joint: The first step in preparing to grease a joint is to locate it on your vehicle. Joints are typically found on the steering and suspension systems and can be found near the wheels or under the car’s chassis.

- Pick the proper grease: It’s essential to select the proper grease for your joint. Most joints require a high-temperature grease that can withstand the heat generated by the joint during operation. Check your vehicle’s owner’s manual or consult with a mechanic to determine the right type of grease for your joint.

- Make the ball joint clean: Cleaning the joint to get rid of any dirt or debris that may have formed on its surface is necessary before applying grease. Use a clean rag or a wire brush to clean the joint thoroughly.

- Taking off the old grease: If there is old grease present in the joint, it’s important to remove it before applying new grease. A special tool called a joint press may be required to remove the old grease, so consult with a mechanic if you’re unsure how to do this.

- Apply grease: It’s time to apply the new grease after the joint is clean and clear of the old grease. Use a grease gun to inject the grease into the joint, being careful not to overfill it.

- Check for leaks: After greasing the joint, check for any leaks or signs of excess grease around the joint. If you notice any leaks, clean the area and reapply the grease as needed.

How to Grease a Ball Joint – Step By Step Guides

Step1. Gather your tools and materials: You will need a grease gun, a tube of high-quality grease, and a jack stand.

Step 2. Locate the ball joint: The joint is usually located between the control arm and the steering knuckle. If you’re unsure of where to look, contact your vehicle’s manual.

Step 3. Raise the vehicle: Using a jack, raise the vehicle and secure it with a jack stand. Make sure the vehicle is stable and will not move while you work on it.

Step 4. Sanitize the ball joint.: To clear the joint of any dirt or debris, use a clean cloth or a wire brush. This will guarantee that the grease will effectively permeate the joint.

Step 5. Attach the grease gun: Remove the dust cap from the grease fitting on the joint and attach the grease gun nozzle. Pump the grease gun until you feel resistance, indicating that the joint is fully lubricated.

Step 6. Wipe away excess grease: After greasing the joint, wipe away any excess grease with a clean cloth. This will prevent any dirt or debris from sticking to the excess grease, which could cause more harm than good.

Step 7. Repeat the process: Repeat the process on the other joints of your vehicle. Be sure to consult your vehicle’s manual for the recommended grease interval and frequency.

How to Know When a Ball Joint is Fully Greased

Here are some steps to follow to ensure that a joint is fully greased:

- Locate the ball joint: The joint is usually found at the bottom of the steering knuckle or the top of the control arm. Refer to the vehicle owner’s manual to locate the joint.

- Clean the area: Use a rag or brush to clean the area around the joint. This step will help remove any dirt, debris, or old grease that may hinder the lubrication process.

- Remove the grease fitting: Use a grease gun to remove the grease fitting from the joint. The grease fitting is a small metal piece that fits over the joint’s lubrication point.

- Apply grease: Using a grease gun, apply grease to the joint’s lubrication point. Keep pumping the grease until you see new grease coming out of the joint. It is better to use the grease that the manufacturer suggests; this information can be found in the owner’s handbook.

- Clean the grease fitting: Once the joint is fully greased, remove the grease gun and clean the grease fitting. This step helps prevent dirt and debris from entering the joint.

- Replace the grease fitting: Replace the grease fitting and tighten it to the manufacturer’s specifications.

Tips for Proper Ball Joint Greasing

- The Best Grease to Use: Not all greases are created equal. Choose a high-quality grease that is specifically designed for joints. It should be resistant to high pressures and temperatures and have a high melting point.

- Use the Right Amount of Grease: Over-greasing or under-greasing joints can cause problems. Too much grease can lead to a buildup of pressure that can damage the joint, while too little grease can cause it to wear out faster. Follow the manufacturer’s recommendations for the amount of grease to use.

- Clean the Joint Before Greasing: Dirt, debris, and old grease can build up around the joint, making it difficult for new grease to penetrate. Clean the joint thoroughly before greasing it. Use a wire brush or a special joint cleaning tool to remove any debris.

- Apply Grease Evenly: Apply the grease evenly around the joint. Use a grease gun with a flexible hose to reach difficult-to-access areas. Rotate the joint while applying the grease to ensure that it is evenly distributed.

- Check for Leaks: After greasing the joint, check for any leaks. Excessive grease can cause it to ooze out of the joint, which can attract dirt and debris, leading to further problems. Wipe away any excess grease and monitor the joint for leaks.

- Follow the Maintenance Schedule: Follow the manufacturer’s recommended maintenance schedule for greasing joints. This will help ensure that they stay lubricated and functioning properly. If you notice any signs of wear or damage, have the joints inspected by a professional.

FAQs About Ball Joint Greasing Process

How often should I grease my ball joint?

The frequency of joint greasing depends on the make and model of your vehicle, as well as your driving conditions. In general, you should grease your joint at least once a year or every 12,000 miles.

What type of grease should I use for my ball joint?

Check your vehicle’s owner’s manual for the recommended type of grease. Lithium-based or synthetic grease is commonly used for joints.

How do I know when my ball joint needs greasing?

You may notice some signs that your joint needs greasing, such as creaking or knocking sounds when you turn the wheel or drive over bumps. You can also inspect the joint for wear and tear.

Can I over-grease my ball joint?

Yes, over- and under-greasing can both be detrimental. Over-greasing a joint can cause wear and tear because the extra grease can trap dirt and debris.

Can I grease a ball joint without a grease gun?

No, you will need a grease gun to inject grease into the joint. A grease gun allows you to apply the grease evenly and precisely.

Can I replace a ball joint myself?

Replacing a ball joint can be a complex and challenging process, so it’s recommended to seek professional help. However, if you have experience in car repairs, you can replace a joint yourself with the right tools and instructions.

How long does a ball joint last?

The lifespan of a joint varies depending on the make and model of your vehicle and your driving conditions. In general, ball joints can last between 70,000 to 150,000 miles.

Is ball joint maintenance necessary?

Yes, joint maintenance is necessary to ensure your vehicle’s safety and longevity. Proper greasing reduces friction and wear, preventing the joint from failing and causing accidents.

Final Thought

In the end, knowing how to grease a ball joint is a critical aspect of vehicle maintenance. By following the steps outlined in this guide and adhering to proper grease intervals, you can help prolong the life of your joint and ensure the safety of your vehicle. Remember to inspect your ball joint regularly and seek professional help if you encounter any issues during the greasing process. By following these best practices and tips, you can keep your joint in top condition and prevent costly repairs down the road. Always prioritize your safety and the safety of others on the road by maintaining your vehicle properly and knowing how to grease a ball joint.

Related Topic:

- When to Use White Lithium Grease on Rubber Bushings

- How To Remove Grease From Hands And Nails

- Where to Put Dielectric Grease on Spark Plugs

- What Happens If You Don’t Grease Brake Pads

- Different Types of Grease

- Can You Use Dielectric Grease on Brake Caliper Pins

- White Lithium Grease vs WD-40

- Is Red and Tacky Grease Good for Wheel Bearings

- what happens if you don’t grease your ball joints