Oil pan torque sequence is a crucial aspect of engine assembly. It involves tightening the bolts on the oil pan in a specific pattern to ensure a secure seal. If not done correctly, it can lead to oil leaks, engine damage, and even failure.

The torque sequence is typically provided by the engine manufacturer and varies depending on the make and model of the engine. It is important to follow the sequence precisely to achieve the correct torque and prevent any damage. Additionally, it is recommended to use a torque wrench to ensure accurate torque values. In summary, proper oil pan sequence is essential for a well-functioning engine and should not be overlooked during engine assembly.

What is an Oil Pan Torque Sequence?

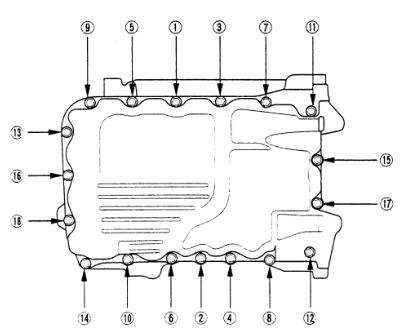

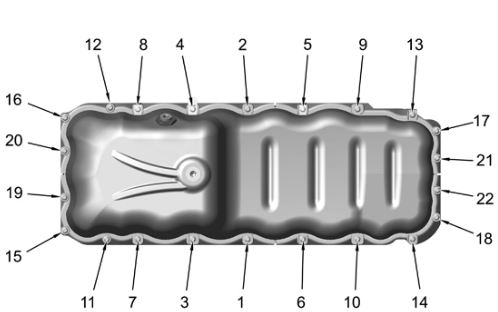

This refers to the specific order in which the bolts on an oil pan are tightened to ensure that the gasket is compressed evenly and the pan is securely attached to the engine block. This is an important step in the installation process, as an improperly torqued oil pan can result in leaks, engine damage, and other issues.

The torque sequence is typically provided by the manufacturer and can vary depending on the make and model of the engine. In general, the sequence will start in the center of the oil pan and work outward in a circular or criss-cross pattern. It is important to follow the sequence precisely and to use a torque wrench to ensure that each bolt is tightened to the correct specification.

In addition to the torque sequence, it is important to use the correct torque specification for the bolts themselves. This information can also be found in the manufacturer’s instructions and should be followed carefully to avoid over-tightening or under-tightening the bolts.

Overall, taking the time to properly torque the oil pan can help ensure that the engine runs smoothly and avoids costly repairs down the line.

Why is the Oil Pan Torque Sequence Important?

When it comes to installing an oil pan, the torque sequence is an essential step that should never be overlooked. The torque sequence refers to the specific order in which the bolts are tightened to secure the oil pan to the engine block. This sequence is critical to ensure that the oil pan is installed correctly and that it remains leak-free.

There are several reasons why the torque sequence is so important. First and foremost, it helps to evenly distribute the pressure and load across the surface of the oil pan. This prevents any stress points from forming, which could cause the oil pan to warp or crack over time. A warped or cracked oil pan can lead to oil leaks, which can cause serious damage to the engine if left unchecked.

In addition to preventing leaks, the oil pan sequence also helps to prevent over-tightening of the bolts. Over-tightening the bolts can cause the oil pan to deform, which can lead to leaks or even cause the bolts to break. On the other hand, under-tightening the bolts can cause the oil pan to vibrate or shift, which can also lead to leaks.

By following the proper torque sequence, the oil pan can be securely fastened to the engine block without any risk of damage or leaks. This ensures that the engine is properly lubricated and protected, which is essential for its longevity and performance.

The oil pan torque is an important step in the installation process that should never be overlooked. By following the proper sequence, the oil pan can be securely fastened to the engine block, preventing leaks and ensuring the longevity and performance of the engine.

How to Perform an Oil Pan Torque Sequence?

Performing an oil pan sequence is a crucial step in ensuring that your engine runs smoothly and efficiently. Here are the steps to follow:

Step 1: Clean the Surface

Before installing the oil pan, it is essential to clean the surface of the engine block where the oil pan will be attached. This will ensure that there is no debris or dirt that could cause the oil pan to leak. Use a scraper or a wire brush to remove any dirt or debris. Then, wipe the surface with a clean, lint-free cloth.

Step 2: Apply Lubricant

Apply a thin layer of lubricant to the surface of the engine block where the oil pan will be attached. This will help the oil pan to seal properly and prevent leaks. Use a clean, lint-free cloth to apply the lubricant evenly.

Step 3: Tighten the Bolts in Sequence

Tighten the oil pan bolts in the correct sequence to ensure that the oil pan is properly secured. The torque sequence will vary depending on the type of engine and the size of the oil pan. Refer to the manufacturer’s specifications for the correct torque sequence and torque specifications.

Here is a general torque sequence to follow:

- Tighten the bolts in a criss-cross pattern, starting with the bolt in the center of the oil pan and working your way outward.

- Tighten each bolt to the manufacturer’s specified torque using a torque wrench.

- Repeat the tightening process, starting with the center bolt and working your way outward, until all bolts have been tightened to the specified torque.

By following these steps, you can ensure that your oil pan is properly secured and that your engine will run smoothly and efficiently.

Common Mistakes to Avoid

When it comes to oil pan torque, there are some common mistakes that can lead to serious problems. By avoiding these mistakes, one can ensure that the oil pan is securely fastened to the engine block, preventing oil leaks and other issues.

Over-tightening the Bolts

One of the most common mistakes that people make when tightening the oil pan bolts is over-tightening them. This can lead to a number of problems, including stripped threads, cracked oil pans, and even engine damage.

To avoid this mistake, it is important to use a torque wrench and follow the manufacturer’s recommended torque specifications. Over-tightening the bolts can also cause the gasket to fail, leading to oil leaks.

Under-tightening the Bolts

Another mistake that people make is under-tightening the oil pan bolts. This can also lead to oil leaks and other problems.

To avoid this mistake, it is important to use a torque wrench and follow the manufacturer’s recommended torque specifications. It is also important to ensure that the bolts are tightened evenly and in the correct sequence.

Skipping the Sequence

Finally, another common mistake that people make is skipping the torque sequence. This can lead to uneven tightening and can cause the gasket to fail, leading to oil leaks.

To avoid this mistake, it is important to follow the manufacturer’s recommended torque sequence. This will ensure the oil pan bolts are tightened evenly and the gasket is properly seated.

Overall, by avoiding these common mistakes, one can ensure that the oil pan is securely fastened to the engine block, preventing oil leaks and other issues.

Frequently Asked Questions

What is the torque for oil pan bolts?

The torque for oil pan bolts can vary depending on the make and model of the vehicle. It’s important to refer to the manufacturer’s specifications for the specific torque required for your vehicle.

How much torque does an oil pan gasket need?

The torque required for an oil pan gasket can vary depending on the make and model of the vehicle. It’s important to refer to the manufacturer’s specifications for the specific torque required for your vehicle.

What is the torque spec for a 350 SBC oil pan?

The torque specification for a 350 SBC (Small Block Chevy) oil pan can vary depending on the year and model. It’s important to refer to the manufacturer’s specifications for the specific torque required for your engine.

Can you over-tighten oil pan bolts?

Yes, it is possible to over-tighten oil pan bolts, which can cause damage to the oil pan, gasket, or even the engine block. It’s important to refer to the manufacturer’s specifications and use a torque wrench to ensure that the bolts are tightened to the correct torque.

What is the torque spec on a 5.3 oil pan?

The torque specification for a 5.3 oil pan can vary depending on the make and model of the vehicle. It’s important to refer to the manufacturer’s specifications for the specific torque required for your engine.

LS timing cover torque sequence?

The LS timing cover torque sequence can vary depending on the make and model of the engine. It’s important to refer to the manufacturer’s specifications and follow the correct torque sequence to ensure proper installation and avoid any potential issues.

Conclusion

The oil pan torque sequence is a crucial step in the installation process of an oil pan. It ensures that the oil pan is tightly secured to the engine block, preventing any oil leaks or damage to the engine.

Following the manufacturer’s recommended torque sequence and specifications is important to ensure proper installation. It is also important to use the correct torque wrench and to tighten the bolts evenly to avoid any warping or distortion of the oil pan.

Related Topics:

- What is Anti Seize Lubricant Used For

- Symptoms of Defective Fuel Pump Driver Module

- Excessive Pressure in Cooling System

- Fuel Pump Won’t Turn On With Ignition

- Car Parts That Need Lubrication

- How to Lubricate Steering Column

- How to Lubricate Sliding Windows

- 5.7 Hemi Cylinder Deactivation Solenoid Location

- How Do Automatic Lubrication Systems Work

- How to Lubricate Sliding Windows