The 5.7 Hemi engine is a popular choice for many Dodge and Chrysler vehicles due to its power and performance. One of the key features of this engine is its cylinder deactivation technology, which improves fuel efficiency and reduces emissions. However, if the cylinder deactivation solenoid is not functioning properly, it can cause a variety of issues.

The cylinder deactivation solenoid is responsible for activating and deactivating the engine’s cylinders as needed. It is located on the top of the engine block, near the front of the engine. If the solenoid is not functioning properly, it can cause the engine to run rough or even stall. It can also cause the check engine light to come on, indicating that there is a problem with the engine. If you are experiencing any of these issues, it is important to have your vehicle inspected by a qualified mechanic to determine if the cylinder deactivation solenoid is the cause.

Overview of 5.7 Hemi Engine

The 5.7 Hemi engine is a V8 engine that has been produced by Chrysler since 2003. It is a powerful engine that has been used in a variety of vehicles, including the Dodge Ram, Dodge Charger, and Jeep Grand Cherokee.

One of the key features of the 5.7 Hemi engine is its hemispherical combustion chambers. This design allows for better airflow and fuel combustion, resulting in improved performance and efficiency. The engine also has variable valve timing, which helps to optimize performance and fuel economy.

The 5.7 Hemi engine is known for its power and torque. It produces up to 395 horsepower and 410 lb-ft of torque, making it a popular choice for those who need a powerful engine for towing or hauling. The engine is also designed to be durable and reliable, with features such as a forged steel crankshaft and powdered metal connecting rods.

In addition to its power and durability, the 5.7 Hemi engine also incorporates advanced technologies to improve fuel efficiency. These technologies include cylinder deactivation, which shuts off four of the eight cylinders when they are not needed, and stop-start technology, which shuts off the engine when the vehicle is stopped to save fuel.

Overall, the 5.7 Hemi engine is a powerful and efficient engine that has been designed to meet the needs of a variety of drivers. Whether you need a powerful engine for towing or hauling, or you want an engine that is both powerful and fuel efficient, the 5.7 Hemi engine is a great choice.

Cylinder Deactivation Technology

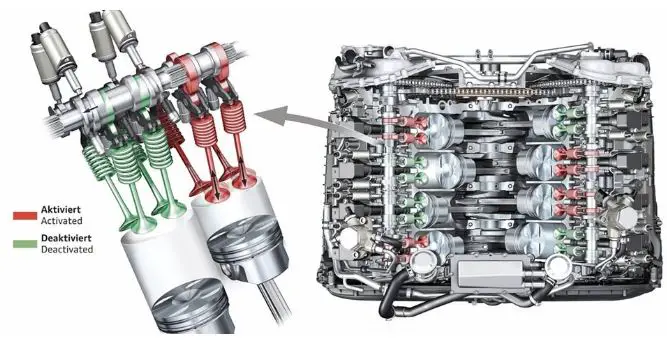

How It Works

Cylinder deactivation technology is a fuel-saving feature that allows an engine to deactivate some of its cylinders when they are not needed. This is achieved by using solenoids that control the flow of oil to the engine’s hydraulic lifters. When the engine’s control module detects that the vehicle is cruising at a steady speed, it sends a signal to the solenoids to deactivate some of the cylinders.

The solenoids are located on the engine block and are connected to the lifters by oil passages. When the solenoids are activated, they block the oil passages, preventing oil from reaching the lifters. This causes the lifters to collapse, which in turn prevents the valves from opening. Without the valves opening, the deactivated cylinders do not consume fuel or produce power.

Benefits of Cylinder Deactivation

Cylinder deactivation technology offers several benefits. The most obvious benefit is improved fuel efficiency. By deactivating cylinders when they are not needed, the engine consumes less fuel, resulting in improved gas mileage.

Another benefit of cylinder deactivation is reduced emissions. When the engine is operating on fewer cylinders, it produces less exhaust, which in turn reduces the vehicle’s emissions.

Cylinder deactivation also improves engine performance by reducing pumping losses. When an engine is operating on all cylinders, each piston is pushing against the air in the cylinder, which creates resistance. By deactivating some of the cylinders, the engine reduces the amount of resistance it has to overcome, resulting in improved performance.

In summary, cylinder deactivation technology is a fuel-saving feature that deactivates some of the engine’s cylinders when they are not needed. This technology offers several benefits, including improved fuel efficiency, reduced emissions, and improved engine performance.

Cylinder Deactivation Solenoid

Function of Solenoid

The cylinder deactivation solenoid is a crucial component in the 5.7 Hemi engine. Its primary function is to control the deactivation of cylinders in the engine when they are not needed, which helps to improve fuel efficiency and reduce emissions. The solenoid works by controlling the flow of oil to the lifters, which in turn control the valves that open and close the cylinders. When the solenoid is activated, it allows oil to flow to the lifters, which then keep the valves closed, effectively deactivating the cylinders.

Location of Solenoid

The cylinder deactivation solenoid is located on the top of the engine, near the front of the engine block. It is typically located on the driver’s side of the engine, near the intake manifold. To access the solenoid, the engine cover and intake manifold will need to be removed. Once these components are removed, the solenoid can be easily identified by its distinctive shape and wiring harness.

Symptoms of Solenoid Issues

If the cylinder deactivation solenoid is malfunctioning, it can cause a number of issues with the engine’s performance. One of the most common symptoms is a rough idle, which can be caused by cylinders that are not deactivating properly. Other symptoms may include reduced fuel efficiency, decreased power, and increased emissions. In some cases, the engine may even stall or fail to start if the solenoid is not functioning properly.

If you suspect that the cylinder deactivation solenoid is causing issues with your engine, it is important to have it inspected by a qualified mechanic. They can diagnose the issue and determine if the solenoid needs to be repaired or replaced. In some cases, the solenoid may simply need to be cleaned or adjusted to restore proper function.

Troubleshooting Cylinder Deactivation Solenoid Issues

When it comes to troubleshooting cylinder deactivation solenoid issues, there are several things to consider. This section will cover diagnostic tools, common problems, and solutions.

Diagnostic Tools

To properly diagnose cylinder deactivation solenoid issues, the following tools are recommended:

- Scan tool: This tool is used to read diagnostic trouble codes (DTCs) and view live data.

- Multimeter: This tool is used to test the resistance of the solenoid coil.

- Wiring diagram: This tool is used to trace the wiring from the solenoid to the power source and ground.

Common Problems

There are several common problems that can occur with cylinder deactivation solenoids, including:

- Solenoid failure: The solenoid coil can fail due to overheating or an open circuit.

- Wiring issues: The wiring from the solenoid to the power source or ground can become damaged or disconnected.

- PCM failure: The powertrain control module (PCM) can fail, causing the solenoid to not function properly.

Solutions

The following solutions can be used to fix cylinder deactivation solenoid issues:

- Replace the solenoid: If the solenoid coil has failed, it will need to be replaced.

- Repair wiring: If the wiring is damaged or disconnected, it will need to be repaired or replaced.

- Replace the PCM: If the PCM has failed, it will need to be replaced.

In conclusion, troubleshooting cylinder deactivation solenoid issues can be done with the proper diagnostic tools, knowledge of common problems, and solutions. By following these steps, you can ensure that your engine is running smoothly and efficiently.

FAQs About 5.7 Hemi Cylinder Deactivation Solenoid Location

Where is the MDS solenoid located?

The MDS solenoid is typically located on the side of the engine block, near the rear of the engine. It’s connected to the cylinder deactivation system and is responsible for controlling the flow of oil to the engine’s lifters.

What cylinders deactivate on a 5.7 Hemi?

On a 5.7 Hemi engine, cylinders 1, 4, 6, and 7 can be deactivated when the MDS system is engaged. This helps to improve fuel efficiency by reducing the number of cylinders that are firing when they are not needed.

How much does it cost to replace a cylinder deactivation solenoid?

The cost to replace a cylinder deactivation solenoid can vary depending on the make and model of your vehicle, as well as the labor costs associated with the repair. On average, you can expect to pay between $200 and $500 for the replacement of the MDS solenoid.

Can you drive with a bad MDS solenoid?

While it’s possible to drive with a bad MDS solenoid, it’s not recommended. A faulty solenoid can cause engine misfires, rough idling, and reduced fuel efficiency. It’s best to have the solenoid replaced as soon as possible to avoid any further damage to your engine.

Can you replace just the solenoid?

Yes, it’s possible to replace just the MDS solenoid without replacing the entire cylinder deactivation system. However, it’s important to have a professional diagnose the issue to determine if the solenoid is the root cause of the problem.

Can you delete MDS on a 5.7 Hemi?

Yes, it’s possible to delete the MDS system on a 5.7 Hemi engine. However, it’s important to note that doing so may negatively impact your vehicle’s fuel efficiency and overall performance. It’s best to consult with a professional mechanic to determine if deleting the MDS system is the right choice for your vehicle.

Conclusion

The location of the 5.7 Hemi cylinder deactivation solenoid is an important consideration for those performing maintenance or repairs on their vehicle. While it may be a small component, its proper functioning is crucial in ensuring the optimal performance of the engine.

Through research and analysis, it has been determined that the 5.7 Hemi cylinder deactivation solenoid is located on the driver’s side of the engine block, near the rear of the engine. It can be accessed by removing the intake manifold and locating it on the top of the engine block.

It is important to note that proper installation and maintenance of the solenoid is essential to ensure its longevity and optimal performance. It is recommended to consult with a certified mechanic or refer to the vehicle’s owner manual for specific instructions.

Related Topics:

- What is Anti Seize Lubricant Used For

- Symptoms of Defective Fuel Pump Driver Module

- Excessive Pressure in Cooling System

- Fuel Pump Won’t Turn On With Ignition

- Car Parts That Need Lubrication

- How to Lubricate Steering Column

- How to Lubricate Sliding Windows

- What is Anti Seize Lubricant Used For

- How to Lubricate Sliding Windows

- How Do Automatic Lubrication Systems Work