Proper lubrication is crucial for the smooth operation and longevity of wheel bearings. These essential components play a vital role in supporting the weight of the vehicle and enabling the wheels to rotate freely. As wheel bearings endure constant stress, friction, and heat, they require adequate lubrication to minimize wear and tear, reduce frictional losses, and prevent premature failure.

Grease, a semi-solid lubricant, is commonly used to lubricate wheel bearings due to its excellent sealing and load-carrying properties. It forms a protective layer between the rolling elements and the raceways, reducing friction and dissipating heat generated during rotation. However, not all greases are suitable for every application, raising the question: Can you use moly grease in wheel bearings?

In this , we will delve into the world of wheel bearings and examine the role of grease in their performance. We will explore the characteristics of moly grease, discuss its advantages and compatibility with wheel bearings, and address the potential risks and alternative options available.

Understanding Wheel Bearings

Wheel bearings are crucial components of a vehicle’s wheel assembly that facilitate smooth and efficient rotation of the wheels. They are designed to support the weight of the vehicle while allowing the wheels to spin freely with minimal friction.

Here are some key points to understand about wheel bearings:

- Function: Wheel bearings enable the wheels to rotate smoothly and carry the weight of the vehicle. They reduce friction between the wheel hub assembly and the axle, allowing the wheels to spin with minimal resistance.

- Construction: Wheel bearings typically consist of an inner and outer race, a set of steel balls or rollers, a cage to keep the balls/rollers separated, and a seal to prevent dirt and moisture from entering the bearing. The inner race attaches to the axle, while the outer race connects to the wheel hub.

- Types of Bearings: There are two main types of wheel bearings: tapered roller bearings and ball bearings. Tapered roller bearings can withstand heavy loads and are commonly used in rear-wheel drive vehicles. Ball bearings are lighter and used in front-wheel drive vehicles.

- Signs of Wear: Over time, wheel bearings can wear out due to continuous use, high temperatures, and exposure to moisture. Common signs of a worn-out wheel bearing include a grinding or humming noise, excessive wheel play or vibration, uneven tire wear, and wheel misalignment. If you experience any of these symptoms, it’s important to have the wheel bearings inspected and replaced if necessary.

- Maintenance: Wheel bearings are generally sealed and do not require regular maintenance. However, they should be inspected periodically during routine vehicle maintenance. If a wheel bearing is damaged or shows signs of wear, it should be replaced promptly to avoid further damage and potential safety hazards.

- Replacement: Wheel bearing replacement is a complex task and typically requires specialized tools. It is recommended to have a qualified mechanic perform this task. During replacement, both the inner and outer wheel bearings are usually replaced as a set.

The Significance of Grease in Wheel Bearings

Grease plays a significant role in the operation of wheel bearings. It is a lubricant that is applied to the bearings to reduce friction, dissipate heat, and protect the bearings from wear and corrosion. Here are the key reasons why grease is important in wheel bearings:

- Friction Reduction: Wheel bearings are subject to high levels of friction as the wheels rotate. Grease forms a lubricating film between the bearing surfaces, reducing friction and allowing smooth rotation. This helps minimize energy loss, improves fuel efficiency, and prevents excessive wear on the bearings.

- Heat Dissipation: As the wheels spin, heat is generated due to friction between the bearing surfaces. Grease acts as a heat conductor, absorbing and dissipating the heat away from the bearings. This helps prevent overheating, which can lead to premature bearing failure.

- Wear Protection: Grease creates a protective barrier between the bearing surfaces, preventing metal-to-metal contact and reducing wear. It forms a cushioning effect that absorbs shocks and vibrations, extending the lifespan of the bearings.

- Corrosion Prevention: Wheel bearings are exposed to various environmental elements, including moisture, dirt, and road debris. Grease acts as a protective barrier, sealing out these contaminants and preventing corrosion on the bearing surfaces. This helps maintain the integrity and performance of the bearings over time.

- Sealing Function: In many wheel bearing designs, the grease also serves as a sealant. It is placed within a sealed bearing assembly, preventing the entry of dirt, water, and other contaminants. This ensures that the bearing remains clean and properly lubricated, enhancing its longevity and performance.

Moly Grease Explained

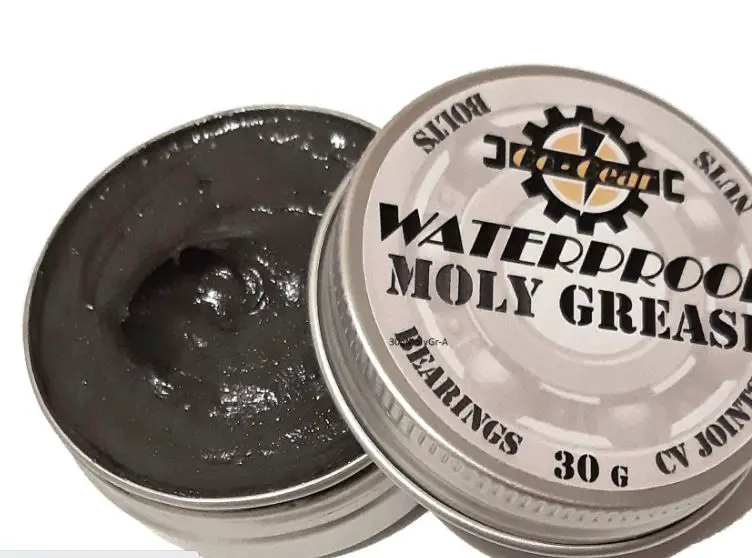

Moly grease, also known as molybdenum disulfide grease or molybdenum grease, is a type of lubricating grease that contains molybdenum disulfide as a key additive. Molybdenum disulfide is a solid lubricant that provides additional lubrication and protection in high-pressure and high-temperature applications. Here’s an explanation of moly grease and its properties:

- Lubrication Enhancement: Moly grease is specifically formulated to enhance lubrication in extreme conditions where conventional greases may fail. The molybdenum disulfide additive forms a thin film on the metal surfaces, reducing friction and wear. This is particularly beneficial in applications where there are heavy loads, metal-to-metal contact, or sliding motion.

- High-Pressure and High-Temperature Performance: Moly grease is known for its excellent performance under high-pressure and high-temperature conditions. The molybdenum disulfide additive has a low shear strength, which means it can withstand heavy loads and resist being squeezed out from the lubricating film. This makes it suitable for applications involving heavy machinery, industrial equipment, and automotive components that operate under extreme conditions.

- Anti-Seizing and Anti-Galling Properties: Moly grease helps prevent seizing and galling, which are common issues in metal-to-metal contact situations. The molybdenum disulfide additive acts as a solid lubricant that fills in microscopic imperfections on the surface, reducing friction and preventing metal components from sticking together or causing damage.

- Corrosion Protection: Moly grease provides corrosion protection to metal surfaces. The grease forms a protective barrier that seals out moisture and contaminants, preventing rust and corrosion. This is particularly important in applications exposed to harsh environments or where there is a risk of water ingress.

- Applications: Moly grease finds application in various industries, including automotive, industrial, and aerospace sectors. It is commonly used in heavy machinery, construction equipment, power tools, gears, bearings, and sliding mechanisms. It is also used in specialized applications such as firearm maintenance and assembly.

Recommended Grease for Wheel Bearings

The recommended grease for wheel bearings depends on various factors such as the type of wheel bearing, vehicle specifications, and operating conditions. Here are some commonly used greases for wheel bearings:

- Lithium Complex Grease: Lithium complex greases are widely used for wheel bearings in most vehicles. They offer good water resistance, excellent lubrication properties, and high-temperature stability. Lithium complex greases provide long-lasting lubrication and can withstand heavy loads and high-speed rotation.

- Synthetic Grease: Synthetic greases, such as those made with polyurea or calcium sulfonate complex, are gaining popularity due to their superior performance in extreme conditions. They have excellent high-temperature stability, water resistance, and mechanical stability. Synthetic greases also offer longer service intervals and extended bearing life.

- High-Temperature Grease: For vehicles operating in extreme temperature conditions or under heavy loads, high-temperature greases are recommended. These greases are formulated to withstand elevated temperatures without losing their lubricating properties. They provide effective lubrication and protection against wear and corrosion in demanding environments.

- Molybdenum Disulfide Grease: Molybdenum disulfide (moly) grease, as mentioned earlier, contains solid molybdenum disulfide particles that provide additional lubrication and protection. It is suitable for heavy-duty applications, such as off-road vehicles and industrial equipment, where extreme pressure and high temperatures are common.

- Multi-Purpose Grease: Multi-purpose greases are versatile and can be used in various automotive applications, including wheel bearings. They provide good general lubrication and protection. However, it’s important to ensure that the multi-purpose grease selected meets the requirements specified by the vehicle manufacturer.

When selecting a grease for wheel bearings, it’s crucial to refer to the vehicle’s owner’s manual or consult with the manufacturer for the specific grease recommendation. They will provide the most accurate information based on the vehicle’s design and operating conditions.

It’s also essential to follow proper greasing procedures, including cleaning the bearing surfaces, applying the correct amount of grease, and adhering to recommended maintenance intervals. Regular inspection and maintenance of the wheel bearings are important to ensure optimal performance, longevity, and safety of the vehicle

Can You Use Moly Grease in Wheel Bearings

Yes, moly grease can be used in wheel bearings. Moly grease, which contains molybdenum disulfide as an additive, provides additional lubrication and protection in high-pressure and high-temperature applications. However, it’s important to note that not all wheel bearings require or are designed for the use of moly grease.

Some wheel bearings, particularly those in modern vehicles, are designed to work with specific types of grease recommended by the manufacturer. Therefore, it is crucial to consult the vehicle’s owner’s manual or contact the manufacturer to determine the appropriate type of grease for your specific wheel bearings.

While moly grease can provide excellent lubrication and protection in certain applications, it may not be suitable for all wheel bearings. Some high-speed or sealed wheel bearings, for instance, may have different requirements. Using an incorrect type of grease can lead to premature wear, decreased performance, or even bearing failure.

To ensure the proper lubrication of your wheel bearings, it is best to follow the manufacturer’s recommendations and use the grease specified for your particular vehicle. This will help maintain the performance and longevity of the wheel bearings while avoiding any potential issues that may arise from using the wrong type of grease.

Potential Risks of Using Moly Grease

While moly grease can be beneficial in certain applications, there are potential risks associated with using it inappropriately or in wheel bearings not designed for its use. Here are some potential risks:

- Incompatibility: Moly grease may not be compatible with certain types of wheel bearings or their seals. Some wheel bearings, particularly sealed bearings, may have specific lubrication requirements that differ from those of moly grease. Using moly grease in such bearings can lead to seal degradation, lubricant contamination, and premature failure of the bearing assembly.

- Excessive Solid Content: Moly grease contains solid particles of molybdenum disulfide, which provide additional lubrication and protection. However, the high solid content can potentially cause issues in certain wheel bearing applications. Excessive solid content can lead to increased friction, inadequate lubrication, and accelerated wear of the bearing surfaces.

- Increased Heat Generation: In some cases, the use of moly grease in wheel bearings can result in increased heat generation. The solid particles in moly grease can create additional friction and heat when the bearing is in operation. This can potentially lead to elevated temperatures, which may exceed the bearing’s designed operating limits and cause premature failure.

- Inadequate Lubrication for Certain Bearings: Some high-speed or sealed wheel bearings have specific lubrication requirements that may not be met by moly grease. These bearings may require greases with different properties, such as lower solid content or specific additives, to ensure proper lubrication and longevity. Failure to use the appropriate grease can result in insufficient lubrication, increased friction, and bearing damage.

FAQ About Can You Use Moly Grease in Wheel Bearings

Can I use moly grease in all types of wheel bearings?

While moly grease is compatible with many types of wheel bearings, it’s essential to consult the manufacturer’s recommendations for your specific wheel bearing type. Certain specialized bearings may require different lubricants.

How often should wheel bearings be re-greased?

The frequency of re-greasing wheel bearings depends on various factors such as the vehicle’s usage, operating conditions, and the type of grease used. As a general guideline, it’s recommended to inspect and re-grease wheel bearings every 30,000 to 50,000 miles or as specified in your vehicle’s maintenance schedule.

Is moly grease suitable for high-temperature environments?

Yes, moly grease is known for its high-temperature resistance and can perform well in elevated temperature conditions. However, it’s crucial to check the specific temperature range indicated by the manufacturer to ensure optimal performance.

Can I mix different types of grease in wheel bearings?

It is generally not recommended to mix different types of grease in wheel bearings. Mixing greases with different formulations can lead to incompatibility issues, resulting in poor lubrication and potential damage to the bearings. It’s best to clean the bearings thoroughly before applying a new grease type.

What are the signs of insufficient or degraded grease in wheel bearings?

Signs of insufficient or degraded grease in wheel bearings include increased friction and heat generation, abnormal noise (grinding or humming), wheel misalignment, uneven tire wear, and excessive play or looseness in the wheel. Regular inspection and maintenance can help identify these issues and prevent further damage.

Final Thought

In the end, the choice of grease for wheel bearings is a critical decision that directly impacts their performance and longevity. While moly grease offers several advantages, including enhanced lubrication and extended service life, it is important to consider various factors before using it in your specific wheel-bearing application.

Throughout this, we have explored the significance of proper lubrication in wheel bearings and the role that grease plays in reducing friction and heat buildup. We have examined the properties and characteristics of moly grease, its compatibility with different types of wheel bearings, and the recommended application techniques.

Related Topics:

- When Not to Use Moly Grease

- Is Red and Tacky Grease Good for Wheel Bearings

- How Often Should You Grease Wheel Bearings on a Car

- Is Wheel Bearing Grease Waterproof

- Can You Over Grease Wheel Bearings

- Can You Use Dielectric Grease on Brake Caliper Pins

- White Lithium Grease vs WD-40

- Is Red and Tacky Grease Good for Wheel Bearings

- what happens if you don’t grease your ball joints