Wheel bearings play a crucial role in the smooth and efficient operation of vehicles, providing a vital connection between the wheels and the axle. Proper maintenance and lubrication of wheel bearings are essential to ensure their longevity and optimal performance. However, there exists a common misconception that more grease is always better for wheel bearings. In this , we will debunk this myth and explore the question: Can you over-grease wheel bearings?

The Importance of Proper Greasing

Proper greasing is of paramount importance when it comes to wheel bearings. These small but critical components play a crucial role in the smooth operation and overall performance of a vehicle. The purpose of greasing is to provide lubrication and reduce friction between the rotating parts of the wheel bearing assembly.

Adequate greasing offers several key benefits. Firstly, it helps minimize friction and wear between the bearing surfaces, allowing the wheels to rotate smoothly. This not only enhances the driving experience but also reduces stress on other components, such as the suspension and steering systems.

Furthermore, proper greasing helps to dissipate heat generated during operation. Wheel bearings can become quite hot due to the combination of rotational forces and friction. The presence of grease ensures that this heat is efficiently dispersed, preventing excessive temperature buildup that can lead to premature bearing failure.

Moreover, grease acts as a protective barrier, preventing contaminants like dirt, dust, and moisture from infiltrating the wheel bearing assembly. These contaminants can cause damage to the bearing surfaces and compromise their performance. Grease acts as a shield, creating a barrier against external elements and extending the lifespan of the wheel bearings.

However, it is essential to strike the right balance when it comes to greasing wheel bearings. While adequate greasing is crucial, over-greasing can have detrimental effects on the bearing’s performance and longevity. Excess grease can lead to higher operating temperatures, increased friction, and even seal damage.

To ensure optimal performance, it is vital to follow the manufacturer’s guidelines regarding the type of grease to use, the recommended quantity, and the greasing intervals. Overgreasing should be avoided as it can result in unnecessary expenses and potential safety risks.

Can You Over Grease Wheel Bearings?

The proper greasing of wheel bearings is essential for their smooth operation and longevity. However, there is a common misconception that more grease is always better. In reality, over-greasing wheel bearings can have detrimental effects on their performance and overall functionality.

1. Debunking the myth: The dangers of over-greasing

Contrary to popular belief, over-greasing wheel bearings can be just as harmful as under-greasing them. When excess grease is applied, it can lead to a range of issues that compromise the bearing’s ability to function optimally.

2. Understanding the limitations of wheel bearing capacity

Wheel bearings have a specific capacity for grease, beyond which the excess grease becomes a liability rather than an asset. Exceeding this capacity can lead to a host of problems and potential failures.

3. Effects of excess grease on wheel bearing performance

Over-greasing can result in several negative effects on wheel bearing performance, including:

a. Increased friction and heat buildup

The excess grease can create additional friction between the rolling elements and the bearing races, generating excessive heat. This heat can cause the grease to break down and lose its lubricating properties, leading to accelerated wear and potential bearing failure.

b. Seal damage and contamination risks

Overfilling the bearing with grease can put excessive pressure on the seals, causing them to rupture or leak. This compromises the integrity of the seal, allowing contaminants such as dirt, water, and debris to enter the bearing assembly. Contaminated grease can accelerate wear, corrode bearing components, and diminish overall performance.

c. Impaired wheel bearing performance and lifespan

Over-greasing can negatively impact the rotation of the wheel bearings, causing them to operate under increased resistance. This puts additional strain on the bearings, leading to premature wear, excessive heat generation, and reduced lifespan. Ultimately, over-greasing can lead to costly repairs and potentially dangerous situations if the bearings fail while in use.

It is important to note that manufacturers provide specific guidelines regarding the appropriate grease quantity and intervals for wheel bearing greasing. Adhering to these guidelines helps ensure optimal performance and longevity while avoiding the risks associated with over-greasing.

Signs of Over-Greased Wheel Bearings

1. Visual Indicators

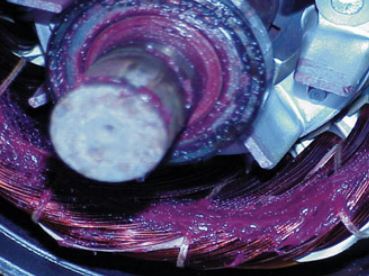

- Excessive grease buildup around the wheel bearing housing: Over-greasing can cause grease to ooze out and accumulate around the wheel bearing housing. This can be observed as a thick, messy layer of grease around the area.

- Grease leakage from the wheel seal: If the wheel seal becomes damaged due to excess pressure from over-greasing, it may result in grease leakage. This can often be seen as grease stains or dripping near the wheel hub or on the wheel rim.

2. Audible Indicators

- Unusual humming or whining noise: Over-greased wheel bearings can produce a distinct humming or whining noise while the vehicle is in motion. This noise may be more noticeable at higher speeds and can indicate excessive friction caused by the excess grease.

- Grinding or grating noise: If the wheel bearings are significantly over-greased, it can lead to a grinding or grating noise. This noise occurs due to the excess grease interfering with the smooth rotation of the bearing balls or rollers.

3. Wheel Bearing Temperature

- Elevated wheel bearing temperature: Over-greased wheel bearings generate additional heat due to the excessive friction caused by the surplus grease. By carefully touching the wheel hub after a drive, you may notice it feels excessively hot to the touch. This increased temperature can indicate over-greasing.

Proper Wheel Bearing Greasing Procedure

To ensure the longevity and optimal performance of your wheel bearings, it is essential to follow a proper greasing procedure. Here is a step-by-step guide to help you grease your wheel bearings correctly:

- Gather the necessary tools: Before you begin, gather the following tools: a grease gun, a clean cloth, safety gloves, a suitable grease recommended by the manufacturer, and a jack or lift to raise the vehicle safely.

- Prepare the wheel: Securely park the vehicle on a level surface and engage the parking brake. If necessary, chock the wheels to prevent any accidental movement.

- Jack up the vehicle: Use a jack or lift to raise the wheel off the ground, allowing you to freely rotate it.

- Remove the wheel: With the wheel off the ground, remove the lug nuts or bolts and carefully take off the wheel, exposing the wheel hub and bearing assembly.

- Clean the wheel bearings: Thoroughly clean the wheel bearings using a suitable solvent or degreaser and a clean cloth. Ensure that all old grease, dirt, and debris are completely removed.

- Inspect the bearings: Inspect the wheel bearings for any signs of wear, pitting, or damage. If you notice any abnormalities, it is recommended to replace the bearings before proceeding.

- Apply the grease: Take a suitable amount of grease and apply it evenly onto the palm of your hand. With the other hand, take one of the cleaned wheel bearings and roll it in your hand, ensuring that the grease is distributed evenly throughout the bearing.

- Pack the bearing: Place the greased bearing into a clean container or bearing packer tool. Use a grease gun to apply additional grease into the bearing until it starts to come out from the other side, indicating that the bearing is fully packed.

- Repeat for all bearings: Repeat steps 7 and 8 for each wheel bearing, ensuring that all bearings are adequately greased.

- Grease the hub: Apply a thin layer of grease onto the wheel hub, ensuring that the entire surface is covered.

- Reinstall the bearings: Carefully place the greased wheel bearings back into the wheel hub, making sure they fit snugly.

- Reinstall the wheel: Put the wheel back onto the hub and hand-tighten the lug nuts or bolts. Lower the vehicle back to the ground and use a torque wrench to tighten the lug nuts or bolts to the manufacturer’s specified torque settings.

- Repeat for other wheels: Repeat the entire greasing procedure for each wheel of the vehicle.

FAQ About Can You Over Grease Wheel Bearings

Can under-greasing be as harmful as over-greasing?

Undergreasing can be equally damaging to wheel bearings. It leads to inadequate lubrication, resulting in increased friction, heat buildup, and accelerated wear. Proper greasing is essential to ensure optimal performance and longevity.

How often should wheel bearings be greased?

The frequency of wheel bearing greasing depends on various factors such as the vehicle type, driving conditions, and manufacturer recommendations. Typically, it is recommended to inspect and regrease wheel bearings every 30,000 to 50,000 miles or as indicated in the owner’s manual.

Is it possible to remove excess grease from wheel bearings?

Yes, it is possible to remove excess grease from wheel bearings. The process involves disassembling the wheel bearing, carefully cleaning the components, and properly repacking the bearings with the appropriate amount of grease. It is advisable to consult a professional mechanic for this procedure.

Can over-greased wheel bearings lead to accidents?

While over-greased wheel bearings may not directly cause accidents, they can significantly compromise vehicle safety and performance. Excessive grease can lead to overheating, seal damage, and increased friction, which can eventually result in wheel bearing failure and unexpected breakdowns. It is crucial to maintain properly greased wheel bearings to ensure safe driving.

What are the consequences of not greasing wheel bearings?

Neglecting to grease wheel bearings can have severe consequences. Without proper lubrication, the bearings experience increased friction and heat, leading to accelerated wear, noise, and potential bearing failure. Insufficient greasing also exposes the bearings to contaminants and moisture, further compromising their lifespan and performance.

Final Thought

In the end, the idea that “more is better” when it comes to greasing wheel bearings is a misconception that can have detrimental effects on their performance and longevity. Over-greasing wheel bearings can lead to a cascade of problems, including increased friction, heat buildup, seal damage, and impaired performance.

Proper greasing is essential for maintaining optimal wheel bearing function. Adequate greasing provides lubrication, reduces friction, and helps dissipate heat, thereby ensuring smooth and efficient operation. However, it is crucial to adhere to manufacturer guidelines and avoid over-greasing, as excess grease can cause more harm than good.

Related Topics:

- Different Types of Grease

- When Not to Use Moly Grease

- Is Red and Tacky Grease Good for Wheel Bearings

- How Often Should You Grease Wheel Bearings on a Car

- Is Wheel Bearing Grease Waterproof

- Can You Use Dielectric Grease on Brake Caliper Pins

- White Lithium Grease vs WD-40

- Is Red and Tacky Grease Good for Wheel Bearings

- what happens if you don’t grease your ball joints