Grease fittings are crucial components in various mechanical systems and machinery, serving the essential purpose of lubrication and maintenance. These small, but vital, devices come in a variety of forms to suit different applications and requirements. In this exploration of lubrication technology, we delve into the world of grease fittings, highlighting the different types and their significance in ensuring the smooth operation and longevity of mechanical equipment.

Whether you’re a seasoned engineer, a machinery enthusiast, or simply curious about the inner workings of mechanical systems, understanding the various types of grease fittings is a valuable piece of knowledge. So, let’s embark on this journey to discover the Grease Fittings and their roles in keeping the wheels of industry turning.

Grease Fitting Materials

Grease fittings, also known as grease nipples or zerk fittings, are essential components in machinery and mechanical systems that require lubrication. These fittings play a crucial role in delivering lubricating grease to moving parts, reducing friction, and ensuring smooth operation. One key aspect of grease fittings is the materials from which they are made, as this greatly influences their performance and durability.

The choice of material for grease fittings depends on various factors, including the application, environmental conditions, and the specific needs of the machinery. Here are some common materials used in the manufacture of grease fittings:

- Steel: Steel grease fittings are among the most prevalent. They are durable, corrosion-resistant, and capable of withstanding high-pressure applications. Steel fittings are often plated with materials like zinc or nickel to enhance their resistance to rust and corrosion.

- Brass: Brass grease fittings are favored for their excellent corrosion resistance, especially in marine and saltwater environments. They are also known for their malleability, making them suitable for various types of machinery.

- Stainless Steel: Stainless steel grease fittings are highly resistant to corrosion and are suitable for use in harsh or corrosive environments. They are also known for their longevity and strength.

- Aluminum: Aluminum grease fittings are lightweight and offer good corrosion resistance. They are commonly used in applications where weight is a critical factor, such as in aerospace and automotive industries.

- Plastic: Plastic grease fittings are used in less demanding applications where corrosion resistance is not a primary concern. They are lightweight and affordable, making them a cost-effective choice for certain applications.

- Copper: Copper grease fittings are relatively rare but find use in specialized applications where their excellent thermal conductivity properties are beneficial. They are also resistant to corrosion.

The selection of grease fitting material should consider factors such as the operating conditions, exposure to chemicals or moisture, temperature variations, and the type of lubricants used. Proper material selection ensures the longevity and effectiveness of grease fittings in maintaining the machinery’s optimal performance.

Types of Grease Fittings

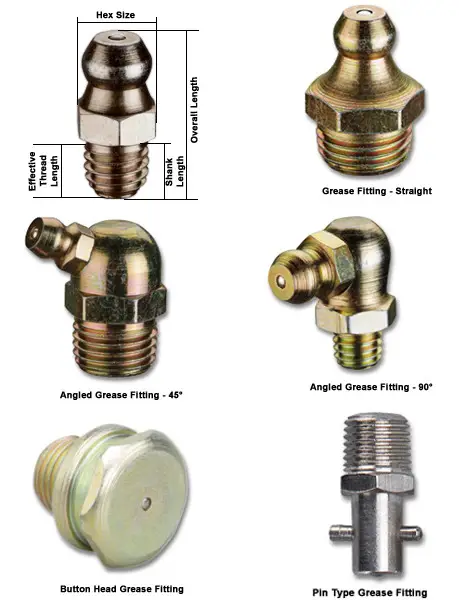

Grease fittings, also known as grease nipples or zerk fittings, come in various types, each designed to meet specific lubrication needs and compatibility with different machinery and systems. These types of fittings facilitate the precise application of lubricating grease to moving parts, reducing friction and extending the lifespan of equipment. Here are some common types of grease fittings:

- Straight or Straight-Drive Fittings: These are the most basic and commonly used grease fittings. They consist of a straight tube with a threaded end for attaching a grease gun. They are suitable for reaching lubrication points that are easily accessible and aligned with the grease gun.

- 90-Degree Fittings: 90-degree grease fittings have an L-shaped design, allowing grease to be injected at a right angle to the fitting. These fittings are useful in tight or hard-to-reach spaces where a straight fitting would be impractical.

- 45-Degree Fittings: Similar to 90-degree fittings, 45-degree grease fittings provide a moderate angle for grease application. They are often employed in applications where a 90-degree angle is too sharp.

- Button-Head or Flush-Type Fittings: These grease fittings have a flat, button-like head that is flush with the surface of the machinery. They are typically used in applications where protruding fittings might interfere with other components or moving parts.

- Drive-Type or Slotted Fittings: Drive-type grease fittings feature a slotted design on the head, allowing for the use of a socket or wrench to install or remove them. They are known for their durability and are often used in heavy-duty applications.

- Pin-Type Fittings: Pin-type grease fittings have a small pin protruding from the center of the fitting. A special nozzle on the grease gun mates with this pin to allow grease to be injected. These fittings are commonly found in agricultural and automotive applications.

- Threaded Push-On Fittings: These fittings are designed for easy installation by simply threading them onto a lubrication point without requiring additional tools. They are quick and convenient to use, making them popular in various industries.

- Flush-Mount Fittings: Flush-mount grease fittings are designed to be flush with the machinery’s surface, providing a smooth and obstruction-free exterior. They are often used in applications where aesthetics or protection against damage is important.

- Grease Fittings with Check Valves: Some grease fittings come equipped with built-in check valves. These valves prevent grease from flowing back out of the fitting after lubrication, ensuring that the lubricant remains in the system and reaches the intended lubrication point.

The choice of grease fitting type depends on factors such as accessibility, space constraints, equipment design, and the specific lubrication requirements of the machinery. Proper selection and maintenance of grease fittings are essential for efficient lubrication and the prolonged life of mechanical systems.

Frequently Asked Questions

What is a grease fitting, and what is its purpose?

A grease fitting, also known as a grease nipple or zerk fitting, is a small device designed to facilitate the precise application of lubricating grease to moving parts within machinery. Its primary purpose is to reduce friction, prevent wear and tear, and extend the life of mechanical components.

How do I choose the right grease fitting for my equipment?

The choice of grease fitting depends on factors such as accessibility, space constraints, equipment design, and the specific lubrication requirements. Consider the location of the lubrication point and the type of machinery you’re working with when selecting a fitting.

How often should I grease my equipment?

The frequency of greasing equipment depends on factors like the type of machinery, its usage, and the manufacturer’s recommendations. Regular maintenance schedules, including greasing intervals, should be outlined in the equipment’s manual.

What type of grease should I use with grease fittings?

The type of grease to use depends on the equipment, application, and operating conditions. Consult the equipment manual or a lubrication specialist to determine the appropriate grease type, consistency, and NLGI (National Lubricating Grease Institute) grade.

Can I over-grease my equipment, and what are the consequences?

Yes, over-greasing can be detrimental to equipment. It can lead to excessive pressure buildup, seal damage, and lubricant waste. Follow manufacturer recommendations for proper greasing intervals to avoid over-greasing.

How do I maintain and clean grease fittings?

Regularly inspect grease fittings for dirt and debris, and clean them before greasing. Use a grease gun with a clean nozzle to avoid contamination. It’s also advisable to replace damaged or clogged fittings promptly.

Are there any environmental considerations when using grease fittings?

Yes, it’s essential to use environmentally friendly grease and dispose of used grease and lubrication equipment properly. Follow local regulations for grease disposal to minimize environmental impact.

What are the signs of a malfunctioning grease fitting or lubrication system?

Signs of issues may include insufficient lubrication, unusual noises, increased friction, and premature wear on equipment components. Regular inspections and maintenance can help detect and address these problems early.

Can I retrofit or upgrade my equipment with different grease fittings?

Retrofitting or upgrading grease fittings may be possible, but it should be done carefully to ensure compatibility and maintain equipment warranties. Consult with equipment manufacturers or specialists for guidance.

Final Thought

In the end, understanding the various types of grease fittings is essential for maintaining and prolonging the life of machinery and equipment in a wide range of industries. Whether you’re working with heavy machinery in construction, automotive vehicles, or industrial equipment, selecting the right grease fitting is crucial for effective lubrication and preventing premature wear and tear.

By recognizing the differences between common types grease fittings, such as straight, 90-degree, button-head, and flush-type fittings, you can make informed decisions about which one to use for specific applications. Each type has its advantages and limitations, so selecting the appropriate fitting ensures that grease is delivered precisely to the components that need lubrication, reducing friction, heat, and the risk of mechanical failure.

Additionally, regular maintenance and proper lubrication of equipment through the correct grease fitting can lead to improved operational efficiency and cost savings by preventing costly breakdowns and repairs. Furthermore, it promotes safety by reducing the risk of accidents due to equipment malfunction.

Related Topic:

- When to Use White Lithium Grease on Rubber Bushings

- How To Remove Grease From Hands And Nails

- Where to Put Dielectric Grease on Spark Plugs

- What Happens If You Don’t Grease Brake Pads

- Different Types of Grease

- Can You Use Dielectric Grease on Brake Caliper Pins

- White Lithium Grease vs WD-40

- Is Red and Tacky Grease Good for Wheel Bearings

- what happens if you don’t grease your ball joints