A grease gun is a handy tool that makes lubricating machinery and equipment easier and more efficient. However, air can become trapped in the gun, causing it to malfunction or deliver less effective lubrication. If you’re having difficulty using your gun, it may be time to remove air from a grease gun. In this step-by-step guide, we will provide you with the knowledge and tools needed to remove air from guns effectively. We’ll cover how to get air out of a grease gun, the tools required, the step-by-step process for removing air, and tips for preventing air from getting trapped in your gun in the future.

Understanding the Importance of Removing Air from a Grease Gun

- Air trapped in a gun can reduce the effectiveness of the lubrication, resulting in inefficient or inadequate lubrication of machinery and equipment.

- Air can also cause the grease gun to malfunction, leading to clogs, leaks, or uneven application of lubricant.

- Removing air from a gun ensures that the lubricant is delivered evenly and consistently, resulting in better performance and longer equipment life.

- A grease gun with air trapped inside can lead to excess wear and tear on machinery and equipment, which can result in costly repairs and downtime.

- Proper lubrication is crucial to the smooth operation of machinery and equipment, and removing air from the gun is an essential step in achieving optimal performance.

- By regularly removing air from your gun, you can avoid potential safety hazards associated with malfunctioning equipment and save money on repairs and replacement costs in the long run.

Tools Required for Removing Air from a Grease Gun

When it comes to removing air from a gun, you’ll need a few essential tools to get the job done right. Here are the tools you’ll need:

- Grease gun: Obviously, you’ll need a gun to remove air from it. Make sure the gun is clean and free of old grease or debris.

- Grease: You’ll need to have the appropriate type of grease to refill after removing the air.

- Clean cloth: Before removing the air, it’s important to clean the gun to prevent any dirt or debris from entering the gun.

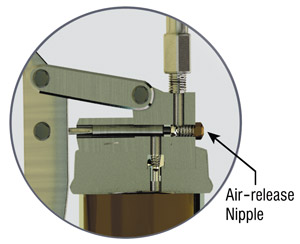

- Wrench: Some require a wrench to remove the head or barrel, which will be necessary to remove the air.

- Screwdriver: In some cases, a screwdriver may be necessary to remove the air vent or bleed screw.

- Clean container: You’ll need a clean container to collect any excess grease that comes out when removing the air.

- Gloves: It’s always a good idea to wear gloves when working with grease to protect your hands and skin.

How to Get Air Out of a Grease Gun: Step-by-Step Guide

Step 1: Prepare the Grease Gun

Before removing air you need to ensure that it is clean and free from any old or contaminated grease. To do this, first, wipe down the exterior of the gun with a clean cloth. Then, pump the gun several times to expel any old grease from the nozzle.

Step 2: Load the Grease Gun

Next, you need to load the gun with new grease. Remove the barrel, and fill it with fresh grease, being careful not to overfill it. Then, reattach the barrel.

Step 3: Prime the Grease Gun

you need to pump it until you see the fresh grease come out of the nozzle. This ensures that all the air is expelled from the gun and that it’s ready for use.

Step 4: Bleed the Air

Hold the nozzle of the grease gun against the fitting and pump the gun’s lever to apply pressure. You will notice air bubbles escaping along with the grease. Keep pumping until only grease is coming out of the nozzle, with no air bubbles.

Step 5: Wipe Down the Grease Gun

Once you have removed the air, wipe down the nozzle and fittings with a clean cloth to remove any excess grease or debris.

Tips for Preventing Air Traps in a Grease Gun

- Use the Right Grease: Choosing the right grease for your equipment is important for preventing air traps. Grease with a thick consistency can cause air bubbles to form, resulting in poor lubrication. Consult the manufacturer’s manual or a professional for advice on the right type of grease to use.

- Avoid Overfilling: Overfilling the grease gun can lead to air being trapped in the tool. Be sure to fill the gun according to the manufacturer’s instructions, leaving some space for air to escape.

- Keep the Grease Gun Upright: Holding the gun at an angle or upside down can cause air to enter the tool. Keep the gun upright and level to prevent air from getting trapped.

- Purge the Grease Gun: Purging the gun before use can help remove any air that may be trapped inside. To purge the gun, pump the handle until grease begins to flow out of the nozzle.

- Store the Grease Gun Properly: Storing the gun with the nozzle facing upwards can help prevent air from getting trapped inside. Ensure that the gun is stored in a clean and dry area to prevent contamination.

Common Problems and Troubleshooting Techniques when Removing Air from a Grease Gun

When removing air there are some common problems that you may encounter. Understanding these issues and their causes can help you troubleshoot the problem and get your gun working again. Here are some of the most common problems that you might encounter when removing air from a gun, along with some troubleshooting techniques:

- Grease won’t come out of the gun: If the grease won’t come out of the gun, it could be due to air pockets blocking the flow. Try pumping the gun slowly and steadily to allow the air to escape and the grease to flow.

- Grease comes out in spurts or unevenly: Uneven grease flow can be caused by air pockets or inconsistent pressure. Pumping the grease gun more slowly and evenly can help resolve this issue.

- The grease gun leaks: If you notice grease leaking from the gun, it could be due to damaged or worn-out seals. Check the seals and replace them if necessary.

- The grease gun won’t hold pressure: If the gun won’t hold pressure, it could be due to a damaged or worn-out piston. Check the piston and replace it if necessary.

- The grease gun becomes clogged: Clogging can occur due to dirty or contaminated grease. Try cleaning the gun thoroughly and using fresh grease to resolve this issue.

Best Practices for Maintaining a Grease Gun after Removing Air

Once you have successfully removed air from your gun, it’s important to follow best practices for maintaining it to ensure it continues to work effectively. Here are some tips to help you maintain your gun after removing air:

- Clean the Grease Gun: After removing the air, it’s a good idea to clean the gun thoroughly to remove any leftover grease or debris. Use a rag or a cleaning solution to wipe down the exterior and interior of the gun, including the nozzle and the grease tube.

- Lubricate Moving Parts: To keep your grease gun operating smoothly, it’s important to lubricate its moving parts regularly. Apply a small amount of lubricant to the handle, trigger, and plunger of the gun. This will help prevent friction and extend the life of your tool.

- Store the Grease Gun Properly: When not in use, store it in a cool, dry place to prevent moisture buildup, which can lead to rust and corrosion. Be sure to follow the manufacturer’s recommendations for storing the tool.

- Replace Worn Parts: Over time, the seals and O-rings in your gun may wear out, causing leaks and reduced performance. If you notice any issues, inspect the seals and O-rings and replace them as needed.

- Use High-Quality Grease: To use high-quality grease that is compatible with your grease gun. Using the wrong type of grease can cause clogs, reduce performance, and potentially damage your tool.

FAQ About How to Get Air Out of a Grease Gun

How do I know if there is air in my grease gun?

By observing the grease flow. If the grease flows erratically or spits out, then there may be air in the gun.

What is the best way to get air out of a grease gun?

The best way to get air is to pump it until the air is forced out. You may need to pump the gun several times before the air is completely removed.

How often should I check for air in my grease gun?

It’s a good idea to check every time you use it. If you notice that the grease is not flowing smoothly, it may be due to air in the gun.

How do I prevent air from getting into my grease gun?

To prevent air ensure that you insert the grease cartridge correctly and remove any air bubbles that may have formed. Also, store in an upright position to prevent any air from getting into the gun when not in use.

What if I can’t get the air out of my grease gun?

If you’re unable to get the air out of your gun, you may need to disassemble the gun and clean it thoroughly. Check the instructions for your particular model for specific cleaning and maintenance steps.

In The End

How to get air out of a grease gun is a crucial step in ensuring its efficiency and effectiveness. By following the step-by-step guide we have provided, you can easily remove air and prevent issues such as clogging, reduced performance, and leaks. Additionally, by following the best practices for maintaining your gun after removing air, you can extend the life of your tool and prevent costly repairs and replacements. Remember to regularly clean your gun, lubricate moving parts, store it properly, replace worn parts, and use high-quality grease. By taking these steps, you can be sure your gun is always ready to deliver the lubrication your machinery and equipment need.

Related Topic:

- When to Use White Lithium Grease on Rubber Bushings

- How To Remove Grease From Hands And Nails

- Where to Put Dielectric Grease on Spark Plugs

- What Happens If You Don’t Grease Brake Pads

- Different Types of Grease

- Can You Use Dielectric Grease on Brake Caliper Pins

- White Lithium Grease vs WD-40

- Is Red and Tacky Grease Good for Wheel Bearings

- what happens if you don’t grease your ball joints